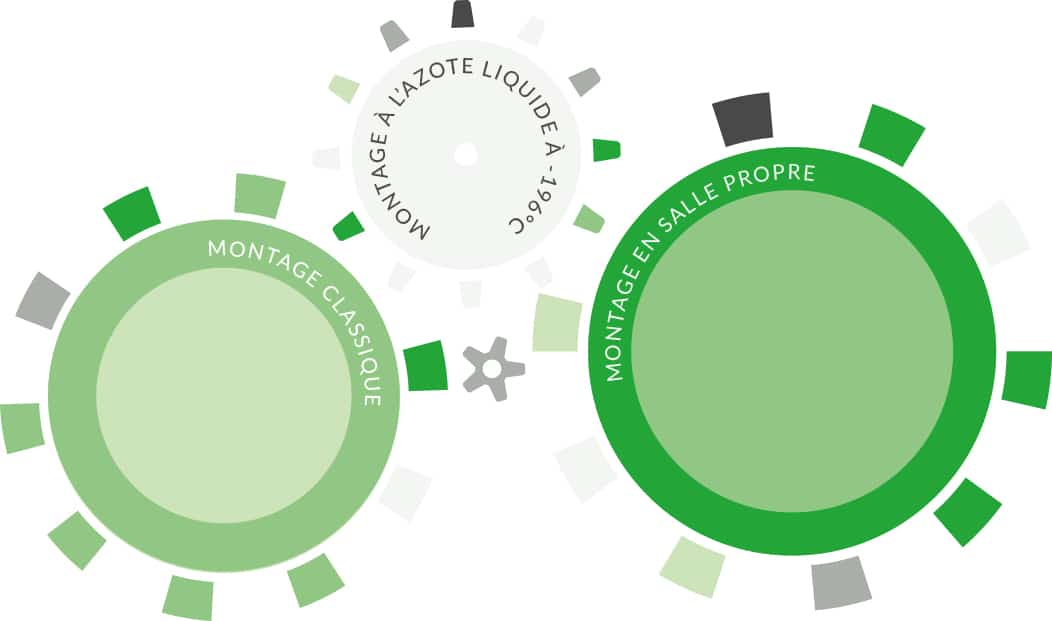

ASSEMBLY

To realise assemblies, we have:

- a 400 m2 workshop dedicated to assembly

- a clean room enabling assembly or conditioning parts somewhere we can handle particles presence

Standard assembly

Your Content Goes HereAssembly of machined parts and commercial supplies (screws, fittings, hoses, seals, sensors, bearings) with inspection of the finished assembly.

Liquid nitrogen assembly at -196°C:

The shrink-fit technique is designed to ensure the cohesion of an assembly made up of two elements, so that they do not burst or deteriorate under pressure.

Assembly in clean room

Control of airborne particles in the room to enable the assembly of sub-assemblies or the packaging of components requiring a high level of cleanliness.

STANDARD ASSEMBLY

To provide complete equipment, we assemble and mount all the machined parts and commercial parts necessary for the operation of the machine (screws, fittings, sensors, bearings, etc.)

LIQUID NITROGEN ASSEMBLY AT -196°C:

Particularly used in aeronautics or automotive, the technique of the frettage is intended to ensure the cohesion of a set composed of two elements, so that they do not burst or deteriorate under pressure. We are equipped to perform cold crimping, also called nitrogen jamming. Liquid nitrogen at -196°C cools the belted element so that it contracts and easily engages in the fret.

ASSEMBLY IN CLEAN ROOM

The term “clean room” has replaced the term “white room” since the publication of standard NF EN ISO 14 644-1 in 1999.