OUR EXPERTISES

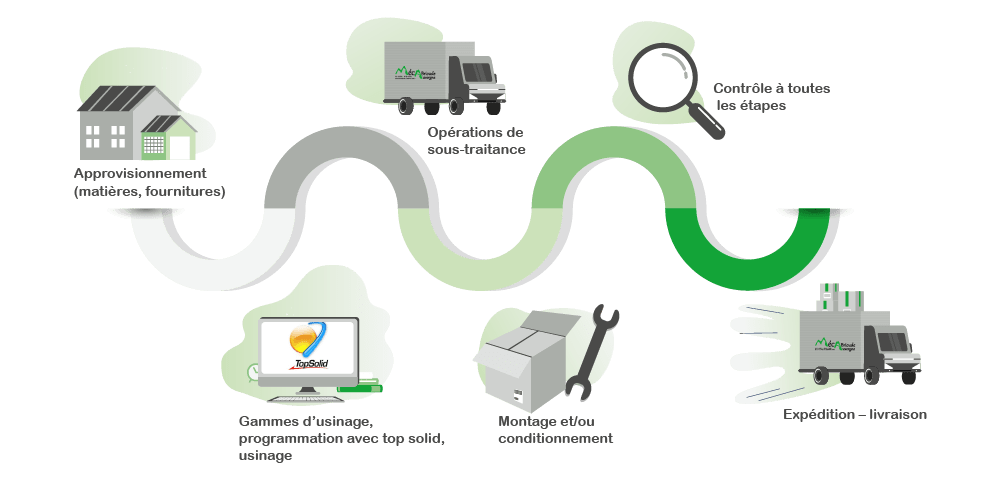

From initial analysis until delivery, we manage supplies, machining, and organize potential subcontracting. We have the equipment and the experts to build assembly, especially in the clean room.

Our teams realise the necessary controls for each step of the process. We attach to reduce our energy consumption waste, optimizing our waste recycling.

ANALYSIS

From your specifications, we check your needs and imperatives. We take care of your sub-assemblies and special machines realization. We define and coordinate all the steps respecting quality requirements in order to provide you with ready-to-use equipment.

We store your files’ data safely with a high level of confidentiality to provide you with our expertise for your next requests. We do have an encryption and storage softwares for all computerised data.

SUPPLY

We order necessary materials to mechanical parts manufacturing according to your specifications and your plan’s specifications and/or final use constraints (mechanics, physics, thermal…). We can supply material certifications according to your needs

Moreover we supply all the commercial parts and supplies, starting from your nomenclatures, after comparing and selecting the best solution available (technically and financially).

internal computerised material stock

internal computerised material stock

We favour local and regional suppliers. Nevertheless we are able to work with worldwide suppliers if needed.

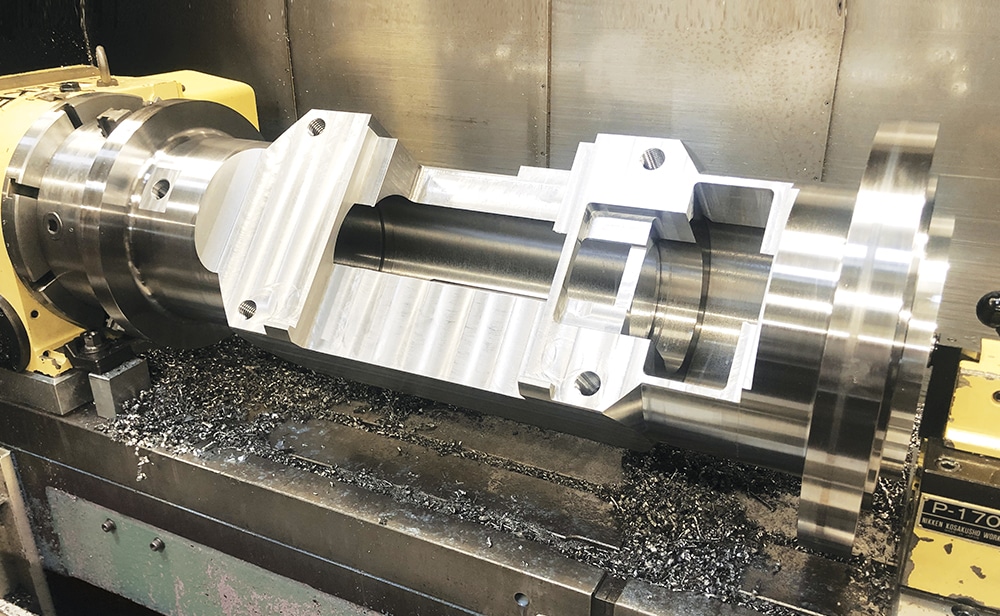

MACHINING

From supplied drawings or from a study made by ourselves:

- we establish the machining range

- we select the most possible high-performance necessary tools

- we create the machine programme for digital device

- we realie different machining operation

- we carry out intermediate and final controls

Machining on a 3-axis CNC machine equiped with dividing head

Machining on a 3-axis CNC machine equiped with dividing head

Our workshop manager coordinates the different operations. Our machine operators, who are qualified, organize their work in an autonomous way with their support, they:

- adjust their tools

- prepare assemblies that could be necessary

- configure their machines

- carrying out their machining, and the fitting

- realizing and/or making realize controls by control department (first parts control, self-control, final controls)

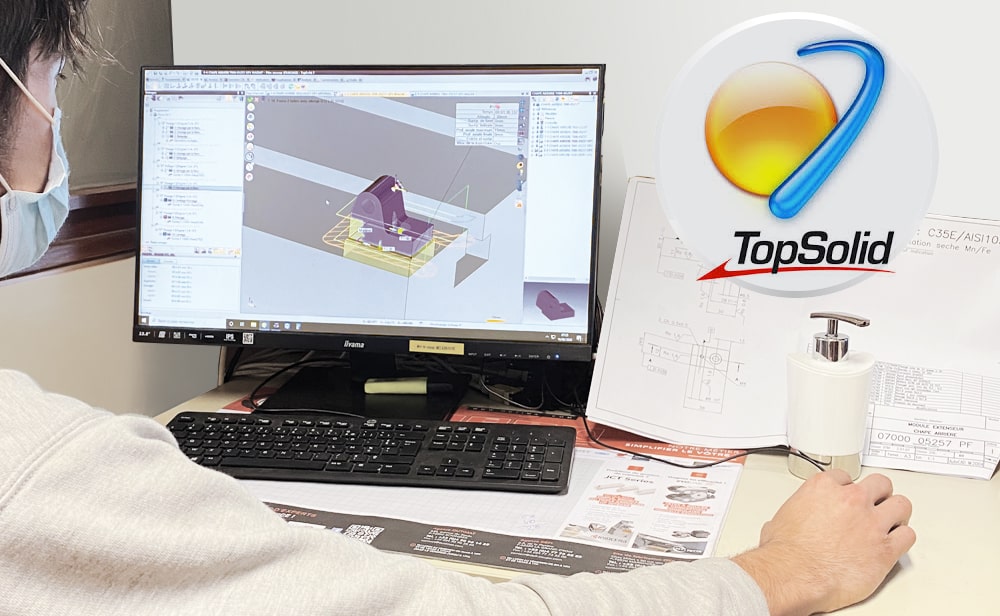

Programme on a TopSolid dedicated personal computer

Programme on a TopSolid dedicated personal computer

To carry out the machining on digital machines, we use your 2D drawings if no 3D file is available (several types of 3D file exist, the most used being the STEP). We create our programmes using Top Solid version 7 software

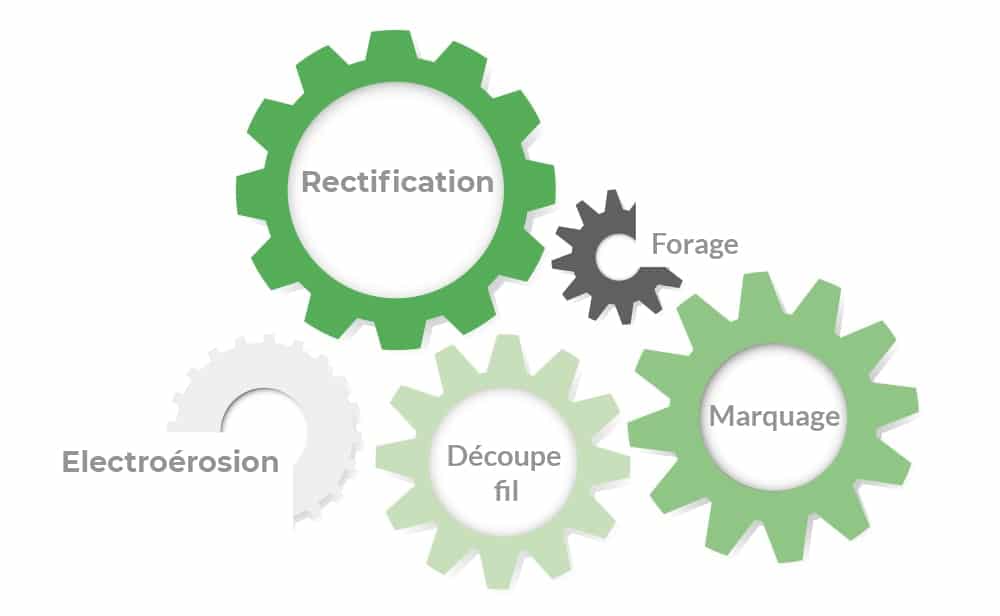

SUBCONTRACTING

Our production manager plans all the subcontracting steps that could be necessary all along the parts or special machines production process. He manages all the logistics as a result.

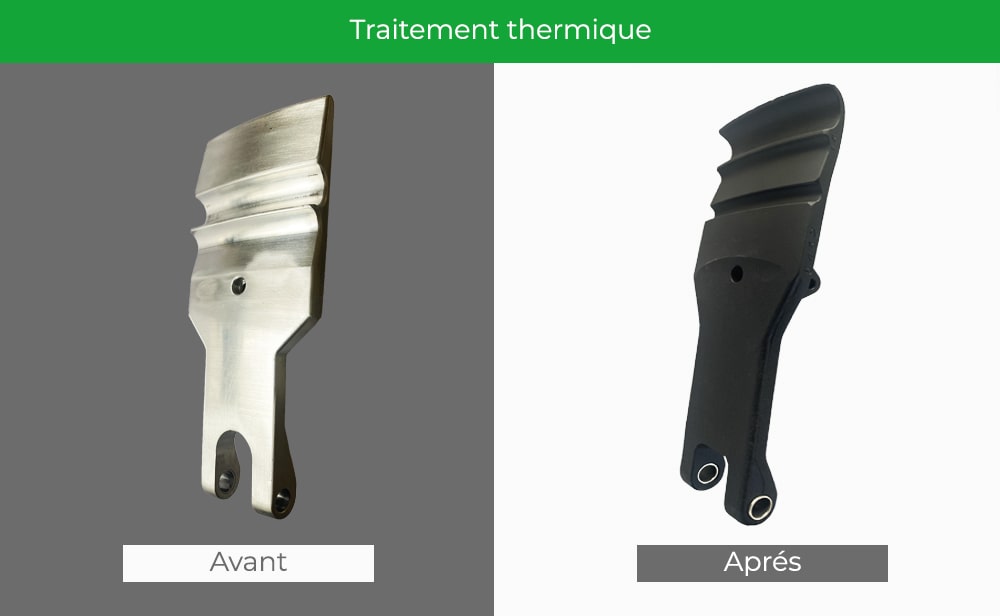

We call on service providers for those operations:

- Mechanic subcontracting with a capacity or a speciality, particularly close to MG63

- surface treatment, heat treatment according to specifications and final necessary technical characteristics.

- other subcontractings for specific tasks…

We favour nearby companies, while evaluating services and cost quality criterias. This is what bring us in other French regions.

I n the context of our quality approach, we evaluate our suppliers and subcontractors, proceed controls before and after subcontracted operations in order to guarantee the conformity of all the delivered sub-assemblies.

n the context of our quality approach, we evaluate our suppliers and subcontractors, proceed controls before and after subcontracted operations in order to guarantee the conformity of all the delivered sub-assemblies.

ASSEMBLY

To supply ready-to-use assemblies, we have:*

- a workshop dedicated to assembly

- with a clean room in which parts can be assembled or packaged in a particle free environment

CONTROL – QUALITY

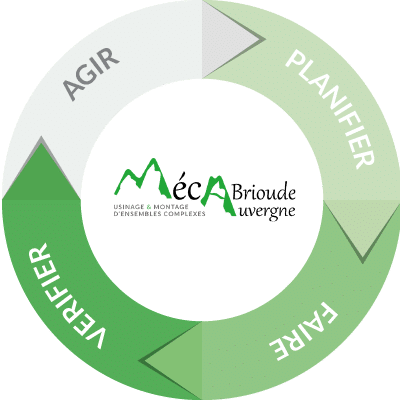

To guarantee the quality of delivered products, we choose to deploy a quality management system for all our processes. We created our quality management in few months according to the ISO 9001 thanks to the work that was previously carried out at MG63 which is certified ISO 9001 since 20 years. Mécabrioude is certified since november 2019.

All the team is involved in the respect of the rules and methodology. Everyone is part of the process and proactive.

To each production step, we set up controls carried out by machine operators or control department:

- Validation control

- First parts control

- Self-control

- Control before – after subcontracting

- Final control

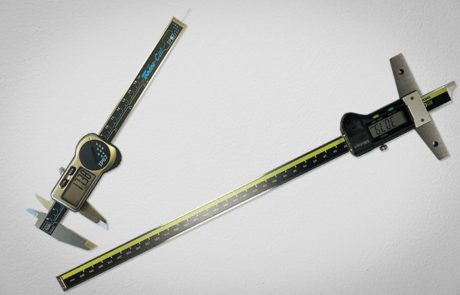

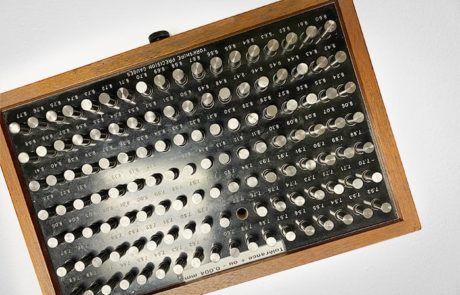

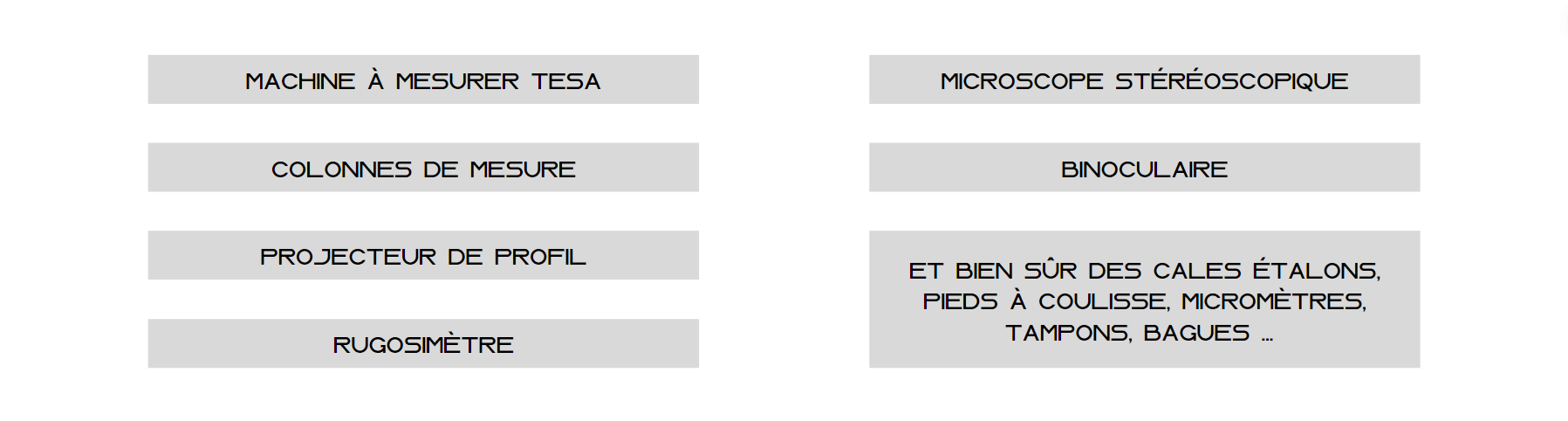

We have:

CONTROL – QUALITY

ACHIEVEMENTS EXAMPLES

Multiple tools models used in tyre production (supply, tools, assembly and control), with more than 40 years of experience.

Especially for the electronic sector, assembly and packaging in a clean room;

Industrial valve equipment;

Parts and sub-assemblies manufacturing in packaging and stationery sectors.